Pump It Up

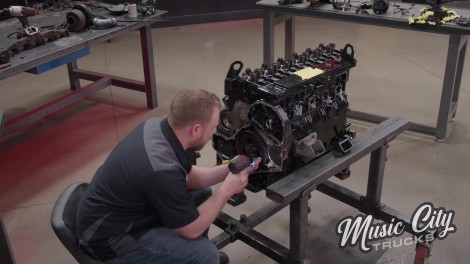

The guys inject some power into their B-series Cummins with a VE to P pump swap on their 93 Dodge Dually, Nightshift, and show you a “cheap trick” to keep your tappets in place while pulling your camshaft.

Season 4

Episode 6

Hosts: Eric Smart, Joel McMillan

First Air Date: June 3, 2024

Duration: 21 minutes 27 seconds