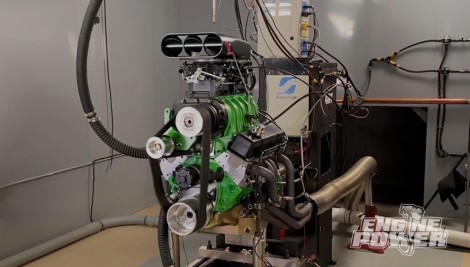

Blown 383 Stroker Has Trouble on the Dyno: What Happened?

The crew from Carcass needs plenty of power to move their 1-ton military truck. Our answer: supercharge a 383 ci V8!

Season 7

Episode 4

Hosts: Mike Galley, Pat Topolinski

First Air Date: February 19, 2020

Duration: 21 minutes 43 seconds