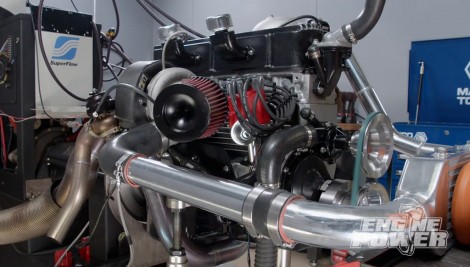

Straight Six on Steroids: Boosting a Chevy 292 Inline Straight-Six

The straight-six engine gets a big horsepower boost with a custom-designed turbo setup.

Season 7

Episode 2

Hosts: Mike Galley, Pat Topolinski

First Air Date: January 31, 2020

Duration: 21 minutes 43 seconds