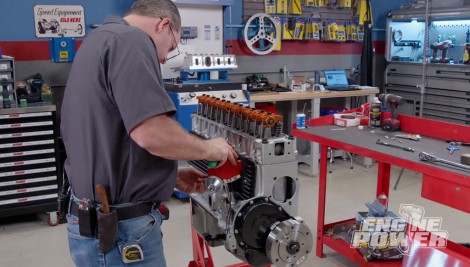

Building a Chevy 292 Inline Straight-Six

We build a hot rod 292 Chevy straight-six that puts power to the pavement for Truck Tech’s 1965 C10.

Season 7

Episode 1

Hosts: Mike Galley, Pat Topolinski

First Air Date: January 14, 2020

Duration: 21 minutes 42 seconds