Crown Vic Cruiser Gets A Junkyard Axle For Its Spec Panther Transformation - Part 2

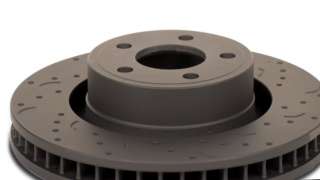

We continue work on our Ford Crown Vic Police Cruiser Spec Panther race car with a rear end swap, suspension mods, and upgraded stopping power.

Season 3

Episode 7

Hosts: Jeremy Weckman, Jimmy King

First Air Date: May 9, 2022

Duration: 21 minutes 30 seconds