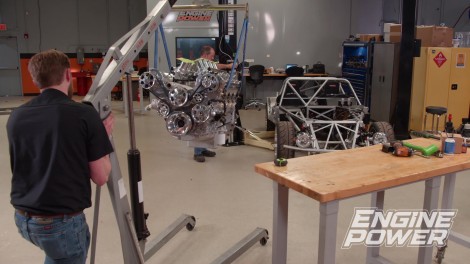

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Lubrication Specialties

Hot Shot's Secret Adrenaline R Series Nano Shift Transmission Fluid

Chattanooga Driveline Service

Steel Driveshaft