Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

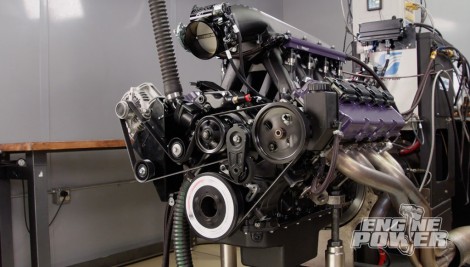

Holley

Induction, Valve Covers, Oil Pan Swap Kit, Accessory Drive Components, Fuel Injection

ARP

ARP Balancer Bolt

ARP

ARP Digital Rod Bolt Stretch Gauge

ARP

ARP Fasteners

ARP

ARP Ultra Torque Lube

Arrington Performance

GEN III Hemi Block, Crankshaft, Hemi Heads, Rod & Piston Assembly

Duralast

Alternator

Goodson Shop Supplies

Intercomp Digital Valve Spring Compressor

Holley

Hi-Ram Intake Manifold

Holley

Mr. Gasket Aluminum Valve Covers

Holley

MSD Blaster Series Coil Packs

Holley

Power Steering Adaper Kit

Matco Tools

MATCO Tools are the Official Tool Supplier to Engine Power

The Industrial Depot

Tools, Hardware, Shop Supplies