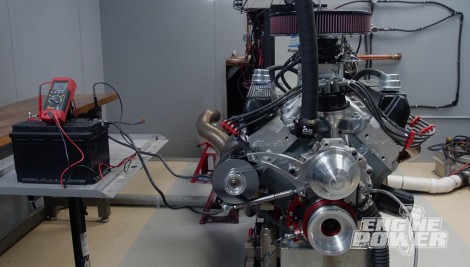

Testing 4 Common Engine Building Myths: Which Ones Are True?

Want to build your best powerplant? It starts with understanding the fundamentals of engine building: valve lash, header sizing, and more!

Season 8

Episode 6

Hosts: Pat Topolinski, Frankie Forman

First Air Date: February 18, 2021

Duration: 21 minutes 35 seconds