Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Cylinder Head Bolts, High Performance, Hex Head, Ford, 351W, with Stock, Edelbrock Performer, RPM Heads, Kit

ARP

Rod Bolt Stretch Gauge, Steel, Dial Indicator, .0005 in. Increments, Adjustable Length, Storage Case, Kit

ATI Performance Products

Harmonic Balancer, Super Damper, Internal Balance, Aluminum, Black, Ford, 289, 302, 351W, 351C, 351M, 400

Cometic Gasket, Inc.

Head Gaskets, 4.080 in. Bore, .040 in. Compressed Thickness, Ford, Small Block, Each

DSS Racing

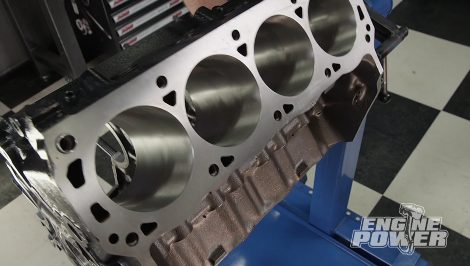

Engine Block, Cast Iron, 4.030 in. Diameter Bore, 1-Piece Rear Main Seal, 2-Bolt Main, Ford, 351W, Each

E3 Spark Plugs

Spark Plug, E3, Gasket Seat, 14mm Thread, .750 in. Reach, Projected Tip, Resistor, Each

Eagle Specialty Products

EAGLE ROTATING ASSEMBLY (BALANCED, .030, H-BEAM ROD, FORGED, MAHLE PISTON -6CC, ESP ARMOR

Federal-Mogul Corporation

Fel-Pro, Oil Pan Gasket, One-Piece, Rubber, Ford, 5.8L, V8, Each

Holley

Carburetor, 4 Barrel, Holley Gen 3 Ultra Dominator, Gasoline - Dual Inlet, 1,150 CFM, Gray Anodized, Each

Howards Cams,Inc.

Camshaft, Retrofit, Hydraulic Roller Tappet, Advertised Duration 306/312, Lift .640/.640, Ford, 351W, Each

Howards Cams,Inc.

Lifters, Street Series, Hydraulic Roller, Vertical Bar, Ford, Small Block, 351C, 351W, Set of 16

Kooks Custom Headers

Headers, Full-Length, Stainless Steel, Natural, 1 7/8 in. Primary, 3.0 in. Collector, Ford, Pair

MSD Ignition

Distributor, Pro-Billet, Magnetic Trigger, Mechanical Advance, Ford, 351W, Each

Quick Fuel Technology Inc.

Carburetor, Black Diamond Q-Series, 950 cfm, Mechanical Secondary, 4-Barrel, Square Bore, Drag Race, Each

Summit Racing

AllStar Performance, Timing Cover, 1-piece, Early Style, Aluminum, Natural, Ford, 302, 351W, Each

Trans-Dapt

Carburetor Adapter, Open Center, Dominator Carburetor, Square Bore Manifold, 2.00 in. Thick, Each

Trick Flow Specialties

Cylinder Head, High Port® 225, CNC Comp Port, Assy, 70cc CNC Chambers, 1.46" Spr, Ti Retain, Small Ford, Each

Trick Flow Specialties

Intake Manifold, R-Series, Single Plane, Aluminum, Natural, 6.429 in. Height, 4-barrel Square Bore, Ford, 351W

Trick Flow Specialties

Rocker Arms, 1.6 Ratio, 7/16 in. Stud, Full Roller Design, Aluminum, Small Ford and 351W, Set of 16

Trick Flow Specialties

Rocker Arm Stud Girdle, Aluminum, Blue, 7/16 in.-20 Thread, Ford, Small Block, Trick Flow® High Port®, Kit

Trick Flow Specialties

Timing Chain and Gear Set, True Roller, Double Roller, Billet Steel Sprockets, Ford, Small Block, Set

Trick Flow Specialties

Valve Covers, Stock Height, 3 in. Overall Height, Cast Aluminum, Black Powdercoated, Small Ford, Pair

Automotive Workwear

The Official Workwear of Engine Power

Spectre Performance

WATER OUTLET FORD V8 SBF

The Industrial Depot

INDUSTRIAL DEPOT - FASTENERS, HARDWARE, AND SHOP SUPPLIES

Trend Performance

CUSTOM LENGTH 3/8 DIA, PUSHROD SET