More '01 Mazda B2500/Ford Ranger "Rolling Thunder" Episodes

More Rolling Thunder Episodes

Trucks! Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Russell Performance

Fitting, Internal Allen Head Pipe Plug, 1/4 in. NPT, Aluminum, Black Anodized, Pair

Russell Performance

Hose, Pro-Classic, Braided Nylon, Black with Blue Tracer, -8 AN, 20 ft. Length, Each

Agent 47

A47 94-04 sn-95 Brake Cooling Kit

APR Performance

Carbon Fiber NACA Duct Type 1, Universal, each

APR Performance

Universal with 5.5" Mirror Lenses (Driver+Passenger Pair), Carbon fiber, GT-3

Las Vegas Tool

The EASYPULLER is the most versatile puller you'll have in your tool box. The tool is easily used by clamping the locking pliers onto any item you want to remove and sliding the 2 lb hammer quickly along the slide bolt to the end creating a powerful pulling force. (Hammering out the item rather than hammering in). By simply removing the 1/4" bolt at the upper jaw and removing the slide hammer assembly the tool can be used as a traditional locking pliers and it comes in a great protective carryin

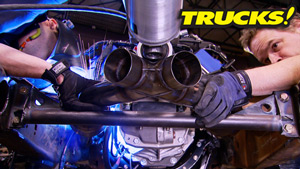

Miller Electric Manufacturing Co.

All-in-one wire welder that welds 24 gauge - 3/16 in. (0.8-4.8mm) mild steel. The simplest Millermatic to set-up and start welding

Wheel Works Inc.

The Wheel Fit wheel test fit tool is the only tool in the world that will physically clamp to an actual tire for the purpose of test fitting the assembly to check all clearances BEFORE ordering your wheels or mounting tires