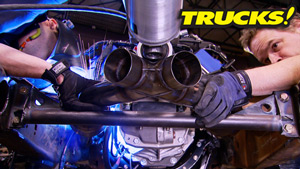

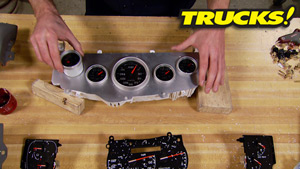

Rolling Thunder Part 2: Engine Fitment

Today we'll make engine mounts for our 4.6 liter V-8 that's going into Project Rolling Thunder and we're making some more room under the hood to house our new stable of 300 plus horses.

Season 12

Episode 3

Hosts: Kevin Tetz, Ryan Shand

First Air Date: April 24, 2010

Duration: 17 minutes 24 seconds