More Wrangler Re-Do Episodes

Truck Tech Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Dupli-Color

Paint, Engine, Enamel with Ceramic Resin, Semi-Gloss, Black, 12 oz., Aerosol, Each

Advance Adapters

Heavy Duty JK Cable Shifter Upgrade

Advance Adapters

Jeep JK Twin Stick Shifter knobs

Advance Adapters

Rubi-Crawler Auxillary Crawl Box For 42RLE Transmission

BDS Suspension

4-1/2" Long Arm Lift Kit - Jeep Wrangler JK 4dr, Customized with: BDS Ultimate Disconnects, Fox 2.0 series high performance monotube gas shocks, BDS front adjustable track bar

Dee Zee

Padlock Crossover Tool Box, Bolt Padlock, Textured Black

PowerStop

Power Stop Z36 Extreme Performance Carbon-Ceramic Brake Pads for Severe-Duty Trucks & Towing

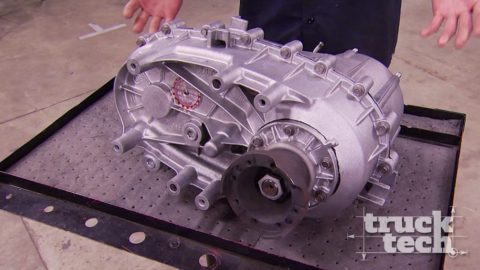

PowerTrain Products

Np241j Jeep Wrangler 2008-03 Rubicon 2006-03 Transfer Case

RimzOne

XD 222 Enduro Machined includes lug nuts, and valve stems Size: 17x8, Bolt Pattern : 5x5.50, Offset : +25

The Industrial Depot

Industrial Depot - Fasteners, Hardware, And Shop Supplies