More '74 Dodge Dart "Pro-Street Dodge" Episodes

MuscleCar Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Magnaflow

Exhaust System, Hot Rod Kit, Header-Back, Stainless Steel, Natural, 3.00 inch Diameter, Universal, Kit

Kooks Custom Headers

Headers, Full Length, Stainless Steel, Natural, 1.875 in. Tube, 3.00 in. Collector, Mopar, Hemi Modular V8, *Custom with unwelded flanges

Specialty Products

Flanging Die, Dimple Die, Steel, Natural, 1.500 in. Outside Diameter, Each

Weld Racing LLC

Wheel, Classic RT, Aluminum, Polished, 15 in. x 16 in., 5 x 4.5 in. Bolt Circle, 6.5 in. Backspace, Each

Matco Tools

1/3 HP Heavy Duty Angle Die Grinder

Matco Tools

Air Saw With Swivel Inlet

Matco Tools

SE4125 Silver Ealge 4-1/2 Angle Grinder

Miller Electric Manufacturing Co.

Portable and powerful 40-amp plasma cutter offers 5/8 in. mild steel cutting. The unit offers easy connection to 120V or 240V input with Auto-Line technology and MVP Adapters

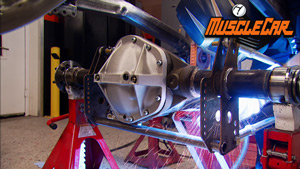

S&W Race Cars

Fits 24", 26" or 28" Universal 4-link rear frame. .22 gauge steel Each kit contains the necessary pieces to install a rear floor in most cars from the front of the rear frame rails to the rear bumper

S&W Race Cars

Fully welded 4-link rear frame packages designed specifically for applications where removing the rear floor pan is either more practical or more desirable. These frames are available in 24", 26" or 28" widths and are jig welded to assure proper alignment of critical suspension mounts

S&W Race Cars

Steel Wheel Tubs Custom Size Made with 22 Gauge Steel (0.031)

Stephens Performance

Used 1972 Mopar Buckets Seats and Front bumper for '74 Dart

Tennsmith

48" Sheet Metal brake with Stand

The Industrial Depot

3x1x1/4 - 60 grit Flap Wheel