Go With the Flow: Performance Pump Tech

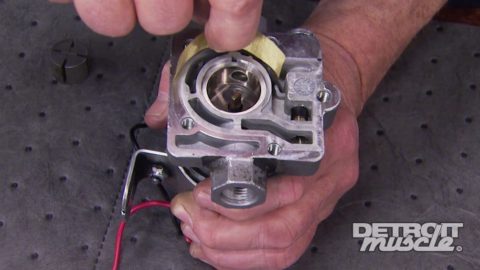

Money Saving How-To: rebuilding fuel, water and oil pumps for more muscle car performance and reliability.

Season 1

Episode 16

Hosts: Joe Elmore, Tommy Boshers

First Air Date: July 19, 2014

Duration: 18 minutes 42 seconds