More '78 Buick Century Wagon "Sucker Punch" Episodes

HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

Assembly Lubricant, for Engine Assembly and Fastener Installation, Ultra Torque, 1/2 pint, Each

ARP

Cylinder Head Studs, Pro Series, 12-Point Head, Pontiac, 400, 428, 455, with Edelbrock Performer Heads, Kit

Comp Cams

Rocker Arms, Ultra Gold, Aluminum, 7/16 in. Stud Mount, Full Roller, 1.5 Ratio, Pontiac, Set of 16

Eagle Specialty Products

Crankshaft, 2-Piece Seal, Internal Balance, Forged 4340 Steel, 4.250 in. Stroke, Pontiac, 400, Each

Edelbrock

Cylinder Head, Performer, Aluminum, Assembled, 87cc Chamber, 215cc Intake Runner, Pontiac, 389-455, Each

Edelbrock

Intake Manifold, Torker II EFI, Aluminum, Natural, Multi-Port, Non-EGR, Pontiac, V8, Each

Hooker Headers

Headers, Super Competition, Full-Length, Steel, Black Ceramic Coated, Pontiac, Firebird, Grand Am, Pair

Milodon

Oil Pan, Steel, Gold Iridite, 7 qt., Pontiac, 350/389/400/421/428/455 , Low Profile Design, Each

Milodon

Water Pump, Mechanical, High-Volume, Aluminum, Natural, Pontiac, 400/428/455, Each

MSD Ignition

Distributor, Pro-Billet, Magnetic Trigger, Mechanical Advance, Pontiac, 326-455, Each

MSD Ignition

Ignition Coil, Blaster HVC-2, U-Core, Drag Race, Square, Epoxy, 45,000 V, Each

Trick Flow Specialties

Fuel Injectors, TFXй 120 lbs./hr., 41A Peak and Hold Circuit Driver, Universal, Set of 8

Turbonetics Inc.

Blow-Off Valve, Godzilla Bypass, Stainless Steel, Polished, 10-35 psi, Universal, Each

Ames Performance Engineering

Timing Cover, Pontiac 400-455

BOP Engineering

Pontiac One-Piece Oil Pan Gasket(OPG49)

Butler Performance

3.75" Tall "Butler Performance Pontiac - "Billet Aluminum Valve Covers-With Bolts"

Butler Performance

Full Service Machine Shop, Engine Builder

Cometic Gasket, Inc.

Custom Head Gasket By Cometic Build to Butler Performance Specifications

Comp Cams

Custom Grind Comp Cam Built To Butler Performance Specifications

Eagle Specialty Products

standard forged 4340 steel H-Beam, length: 6.700 in.

rod journal: 2.200 in.

housing bore: 2.3250 in.

pin size: 0.990 in.

big end width: 0.9900 in.

pin end width: 1.1250 in.

thickness above pin: 0.220 in.

typical weight: 805g

Milodon

Viton Rear Main Seal, Pontiac

RideTech

1978-88 Chevy G-Body, Complete Coil-over System, includes single adjustable Coil-Overs, StrongARM Control Arms, and a rear AirBar.

Ross Racing Pistons

Custom Ross Racing Piston Built to Butler Performance Specifications

Total Seal

Custom Set of Piston Rings for Turbo Ponitac Motor

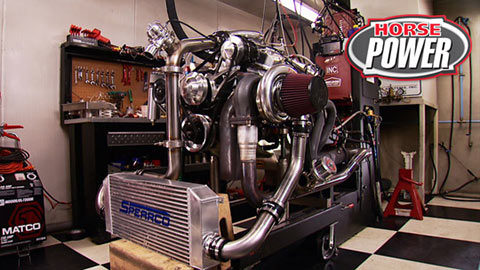

Turbonetics Inc.

Spearco Custom Air/Air Intercooler

Turbonetics Inc.

Turbocharger 88mm