Operation 408 Stroker Windsor Project Still In Progress!

Mike and Pat have been working hard on the 351 Windsor turned 408ci stroker project. If you’ve been following along, you know that our Windsor block was torque plate honed in-house with the help of our Sunnen SV-15 cylinder honing machine. Fun fact – this particular machine can hone cylinders from 0.00750 all the way up to 8″ in diameter. It can also hone cylinders up to 11″ in length.

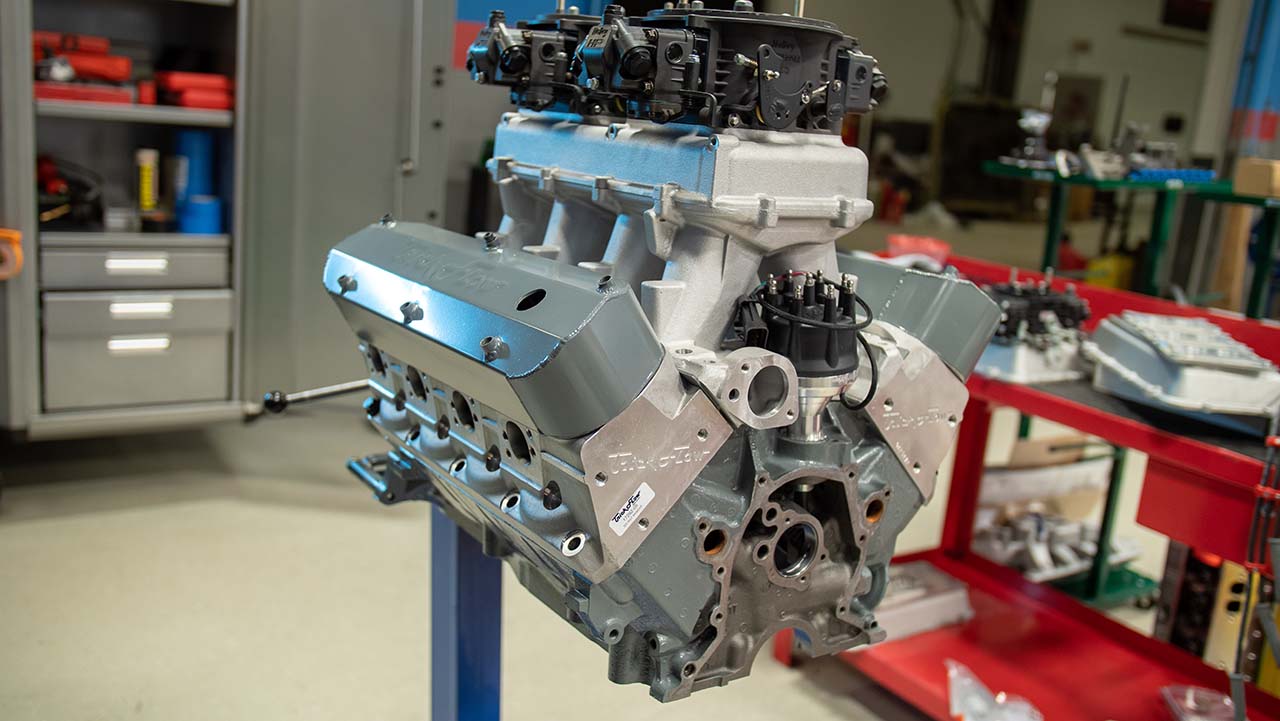

Also, the 408 Windsor was mocked up already sporting two Dominators on a high ram. Pat says the future version will be testing a few induction packages. According to Pat, the final iteration could be a “full bore race bullet sporting an aftermarket block, big solid roller cam, and some compression worthy of Q16”. There’s still plenty of work that needs to be done to complete the project.

Today, we stopped by the Engine Power shop and they were using their Matco digital torque wrench. According to Pat, the Windsor has an impressively low 11 lb-ft of breakaway reading. Other cheaper torque wrenches definitely do the of course, but it’s helpful to have that digital reading right there handy and right in front of you.

Pat was also working on the mounting boss on the small block Ford oil pump. Sometimes it is not parallel to its mating surface sometimes causing a stress point when the fastener is tightened. FLattening the top where the bolt head sits will ensure even pressure and accurate torque. This can be easily checked by putting the bolt in the hole and looking to see if it is crooked. If it’s not, careful work with a carbide burr, dial caliper, and file will help you fix it right! Tune into the HISTORY channel at 7:30 a.m. ET (or set those DVRs) Sunday mornings because you don’t want to miss what’s happening in the Engine Power shop!