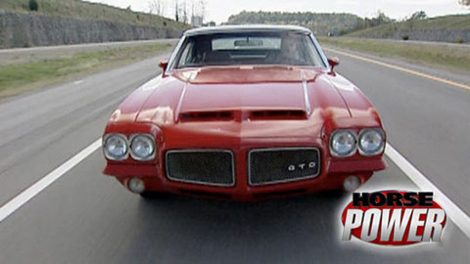

HorsePower Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

BF Goodrich

245/40R18, 275/40R18 series tires.

Fat Man Fabrications

2 inch drop spindles.

Flowmaster

Plant Tour.

Intro Wheels

18X8, 18X9.5 polished custom wheels.

Unisteer Performance Products

Quick ratio power steering gearbox.

Wilwood Engineering

13 inch rotors, composite smart pads.