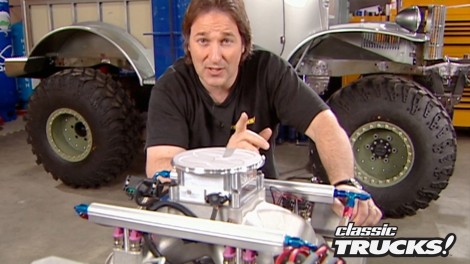

Big Block Mopar For Sergeant Rock

We explore engine choices for the Sergeant Rock project, opting for a beefy 850 horsepower Mopar engine.

Season 7

Episode 20

Hosts: Stacey David

First Air Date: June 1, 2015

Duration: 18 minutes 7 seconds